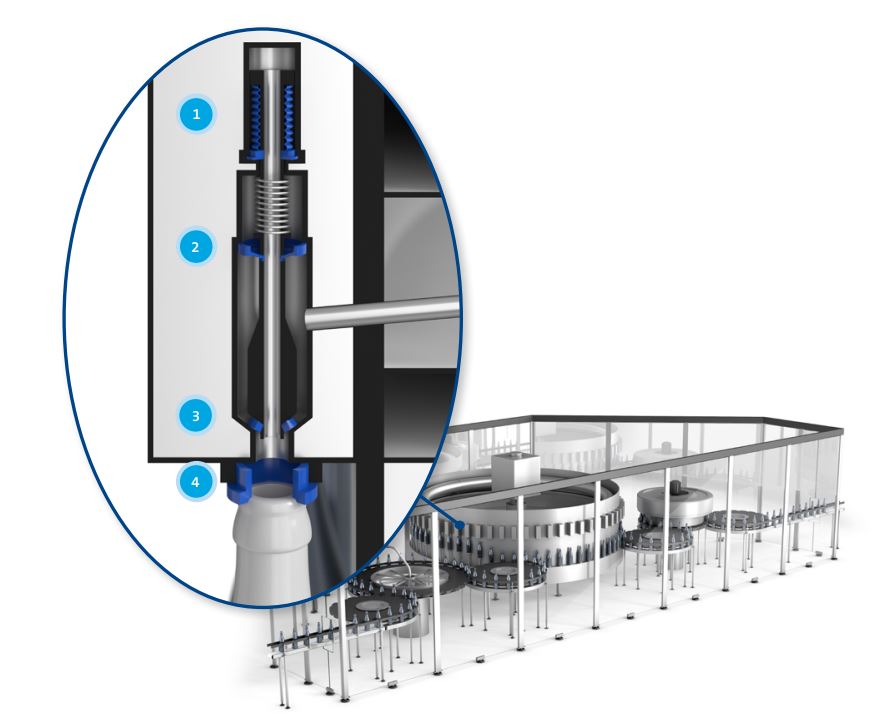

Bottling lines allow manufacturers to rapidly fill thousands of bottles perfectly making them a key element in food & beverage manufacturing facilities. While this equipment is incredibly efficient and has allowed manufacturers to greatly increase production, it offers some unique challenges for sealing solutions. Seals experience rapid and repetitive movements, challenging media, and are required to meet high purity standards often set by the FDA.

With these demanding applications and strict requirements, sealing manufacturers need a lot of expertise and specialized materials/ designs. Today we are going to highlight our Distributor Fredenberg-NOK Sealing Technologies and their brand of Freudenberg seals designed specifically for bottle filling and process industry applications.

Specialized sealing materials for the Food & beverage Industry

When you are working with food and beverage manufacturing or applications it is critical to prevent flavor and aroma transfers to preserve the unique flavors of the foods or beverages. Flavor transfer can occur when you transition your bottling line from one SKU to another because the elastomer absorbs the flavoring.

Freudenberg-NOK Sealing Technologies allrounder material Fluoroprene XP solves the issue. It absorbs only a small fraction of the flavoring without releasing it and guarantees that foods and beverages retain their original flavor. Fluoroprene XP is a very versatile material thanks to its high performance while simultaneously being a cost-effective solution, and is utilized in a wide range of seal types including O-rings, customized parts, diaphragms, clamp seals, Hygienic Usit rings, and machined seals. 75 FKM 239961 is another Fluroelastomer that is well suited for the food and beverage industry: it is peroxide cross-linked and complies with the latest regulations for sealing materials that are in direct contact with products. Additionally, 75 FKM 239961 offers good media resistance and high purity standards making it a suitable option for many applications.

EPDM is one of the most commonly used materials in the food & beverage industry and is well-suited for O-rings, diaphragms, and customized parts. The Freudenberg premium brand family offers some very high-performing materials including 60 EPDM 290, 70 EPDM 291, and 85 EPDM 292 that have shown in testing to perform very well in Integrated Clean-In-Place (CIP) and Sterilize-In-Place (SIP) media. During testing 70 EPDM 291 shows very good resistance to the CIP/SIP media and the associated demanding conditions (e.g. in steam up to 180°C/356°F). All three of the Freudenberg EPDM products were shown to be able to withstand different product media, from beer wort to fatty chocolate and various beverages.

Radial Shaft Seals designed for the food & beverage industry

With aggressive product media that require hygienic standards, Freudenberg-NOK has developed multiple solutions such as the Radiamatic HTS II, the Simmerring® BlueSeal, and the Simmerring® B2PT.

These solutions are well suited to this application because they are designed for only high-performance materials to come into contact with the product media with materials such as PTFE or Fluoroprene XP.

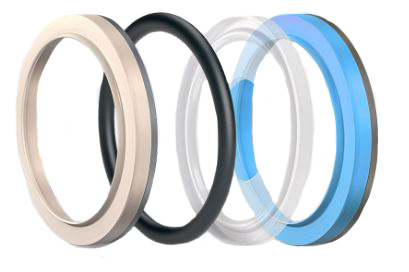

O-ring solutions for the Food & beverage industry

O-rings are one of the most common seals to find in any application.

Freudenberg-NOK manufactures O-rings in a variety of materials specially designed for the food & beverage industry such as 70 EPDM 291, 75 Fluoroprene XP 41, or 75 Simriz® 494.

They also provide other shapes beyond the standard round O-ring like oval, rectangular, semicircular, and x-shaped cross-section seals.

With hundreds of thousands of seals in stock, GFS and Freudenberg Sealing Technologies can assist with all your O-ring needs.

Hygienic product line

Many applications in the process industries require sealing solutions that are specially tailored to meet highly regulated purity standards. Freudenberg-NOK Sealing Technologies has developed a unique product portfolio designed just for the requirements of these applications. This includes various sealing solutions, the Radiamatic HTS II 9539 VL, or aseptic O-rings. A special highlight is the Hygienic Pressure Seal made of a combination of Fluoroprene XP or EPDM and PTFE Quantum that prevents dead spaces thanks to a flat contact surface to the process medium.

Other sealing solutions designed for bottle-filling lines

Beyond the sealing solutions listed above the Freudenberg premium brand offers the right solution for the special needs of bottle filling lines and the food & beverage industry as a whole in a variety of other sealing types including:

- Clamp seals

- Diaphragms

- V-seals

- Packings

- Custom parts

- + Many more

FDA-approved sealing materials

While many manufacturers are highly concerned with the purity of their products and preventing flavor transfers oftentimes they are required to follow set guidelines. In the United States, the regulations are set by the Food and Drug Administration or FDA. Agencies such as the FDA ensure that anything that comes into contact with the product doesn't contain harmful chemicals or contaminants that could transfer into the food or compromise its safety aren't present.

Freudenberg-NOK offers a vast portfolio specifically designed to meet the requirements of the FDA, European Union, and other international requirements to ensure their seals are safe for use with food & beverage applications. Freudenberg-NOK Sealing Technologies offers special sealing materials that comply with global regulations, such as FDA, EG (Reg.) 1935/2004, and EU (Reg.) 10/2011. This portfolio contains different EPDM variants, silicones, PTFE compounds, Polyamide and Polyethylene.

With Freudenberg-NOK’s vast portfolio of sealing solutions designed for process industries and our in-house sealing experts, our team here at Gallagher Fluid Seals is perfectly suited to get you the bottle-filling seals that work best for your applications. Reach out today to find out how our partnership with Freudenberg-NOK Sealing Technologies can ensure you a steady supply of high-performance and hygienic seals.

For more information, contact Gallagher Fluid Seals today.

This article was written by Quincy Wert, Marketing Specialist at Freudenberg-NOK Sealing Technologies. FST is a proud partner of Gallagher Fluid Seals.